Wind turbines have become a pivotal component in the global shift towards renewable energy, contributing to the significant reduction of carbon emissions. According to the Global Wind Energy Council, the total installed capacity of wind power worldwide reached 743 GW in 2020, underscoring the increasing reliance on this sustainable energy source. However, the successful operation and longevity of wind turbines depend heavily on effective maintenance strategies. As the industry grows, so does the necessity for operators to adhere to best practices that ensure optimal performance and minimize downtimes.

Efficient maintenance of wind turbines is critical not only for maximizing energy output but also for minimizing operational costs. A report by the U.S. Department of Energy indicates that proper maintenance can reduce turbine downtime by up to 20%. This emphasizes the importance of implementing a structured maintenance schedule, utilizing advanced monitoring technologies, and developing a responsive maintenance culture among operational teams. As the wind energy sector continues to evolve, adopting these essential tips for maintaining wind turbines efficiently will help ensure that this renewable resource remains a reliable foundation for sustainable energy in the future.

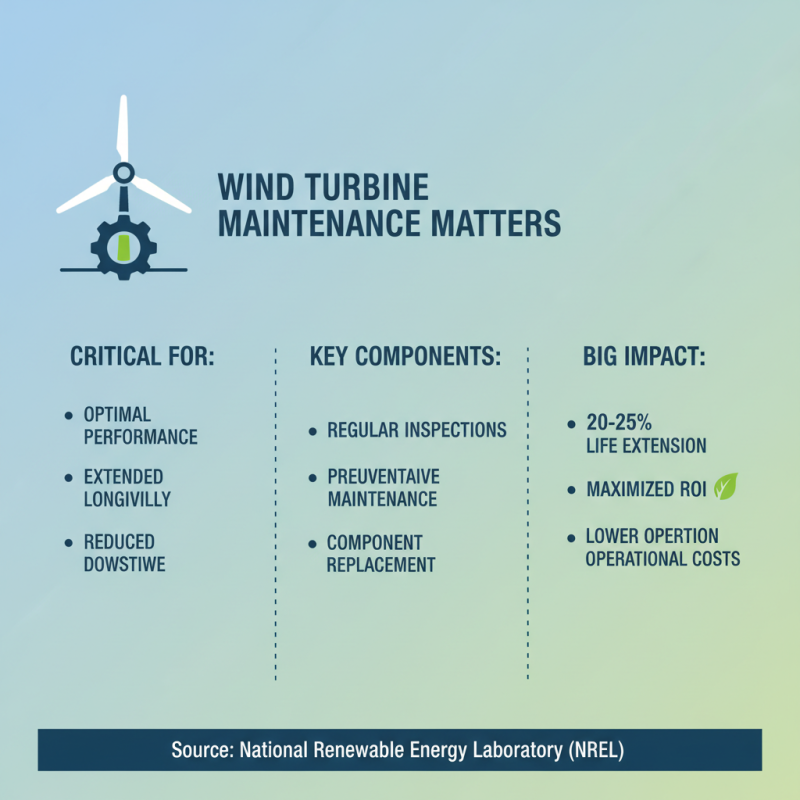

Maintaining wind turbines is critical to ensuring optimal performance and longevity. A well-structured maintenance program focuses on several essential components that can significantly reduce downtime and operational costs. According to the National Renewable Energy Laboratory, regular inspections and preventative maintenance can extend the life of a wind turbine by up to 20-25%, maximizing return on investment.

One of the crucial aspects of a wind turbine maintenance program is the performance monitoring system, which involves real-time data collection and analysis. This system helps identify any anomalies or inefficiencies in turbine operation. Implementing advanced predictive maintenance technology can further enhance this process. It uses data-driven insights to anticipate potential failures before they occur, thus allowing for timely interventions. **Tip:** Regularly update software and algorithms for these monitoring systems to ensure accurate data analysis and effective troubleshooting.

Additionally, effective component management is vital for turbine reliability. Key components such as gearboxes, pitch systems, and blades require regular inspection and maintenance. The International Renewable Energy Agency reports that over 40% of wind turbine failures are related to these elements. Therefore, a systematic maintenance schedule, which includes lubricating moving parts and checking for wear and tear, is essential. **Tip:** Establish a routine that includes thorough visual inspections every six months to identify any physical damages early on, thereby reducing the risk of major repairs down the line.

Regular inspections and monitoring are crucial components of maintaining wind turbines efficiently. These procedures help identify potential issues early on, preventing costly repairs and ensuring that turbines operate at peak performance. By establishing a consistent inspection schedule, operators can thoroughly assess the mechanical and electrical systems, including gearboxes, rotor blades, and control systems. This proactive approach is essential to maximizing the lifespan of the equipment and minimizing downtime.

Moreover, the importance of real-time monitoring cannot be overstated. Advanced technologies such as sensors and data analytics enable operators to track the performance of each turbine continuously. This data can reveal patterns and anomalies that might indicate emerging problems. Utilizing this information allows for timely interventions, reducing the risk of catastrophic failures. By recognizing trends in operational data, maintenance teams can implement predictive maintenance strategies that conserve resources and optimize turbine availability. Regular inspections combined with robust monitoring create a comprehensive maintenance plan that enhances the reliability and efficiency of wind energy production.

| Tip | Description | Frequency | Responsible Party |

|---|---|---|---|

| Regular Inspections | Conduct thorough visual and mechanical inspections to detect any issues early. | Monthly | Maintenance Team |

| Lubrication | Ensure all moving parts are properly lubricated to prevent wear and tear. | Quarterly | Maintenance Team |

| Electrical System Checks | Inspect electrical connections and equipment for any signs of damage or wear. | Bi-Annually | Electrical Engineer |

| Condition Monitoring | Use sensors and software to monitor the health of turbine components. | Continuous | Operations Team |

| Blade Maintenance | Inspect and clean turbine blades to maintain aerodynamic efficiency. | Annually | Maintenance Team |

| Data Analysis | Review operational data for trends that suggest maintenance needs. | Monthly | Data Analysts |

| Safety Training | Regularly train staff on safety protocols and emergency procedures. | Semi-Annually | Safety Officer |

| Environmental Assessment | Evaluate the environmental impact and ensure compliance with regulations. | Annually | Environmental Officer |

| Retrofitting | Upgrade equipment to improve performance and extend lifespan. | As Needed | Engineering Team |

In today's energy landscape, the efficient maintenance of wind turbines is paramount. One of the leading methodologies to enhance the operational longevity and efficiency of these turbines is through data-driven approaches, specifically utilizing predictive maintenance techniques. By harnessing the power of data analytics, operators can anticipate potential issues before they escalate, ensuring minimal downtime and optimal performance.

A key tip for effective predictive maintenance is to implement a robust data collection framework. This involves equipping turbines with sensors that can monitor various parameters such as vibration, temperature, and wind speed in real-time. By analyzing this data, maintenance teams can identify patterns and anomalies that could indicate impending faults. Regularly reviewing this information not only aids in timely interventions but also informs longer-term maintenance strategies.

Another essential tip is to leverage machine learning algorithms to enhance predictive models. These algorithms can process vast amounts of operational data to improve prediction accuracy. By continuously refining the models based on historical performance and failure data, wind farm operators can significantly reduce maintenance costs and improve turbine availability. Engaging with this data-driven mindset not only streamlines the maintenance process but also contributes to the sustainable operation of renewable energy resources.

This chart illustrates the estimated costs associated with different wind turbine maintenance strategies. Predictive maintenance is shown to be the most cost-effective approach, helping to reduce expenses compared to reactive maintenance methods.

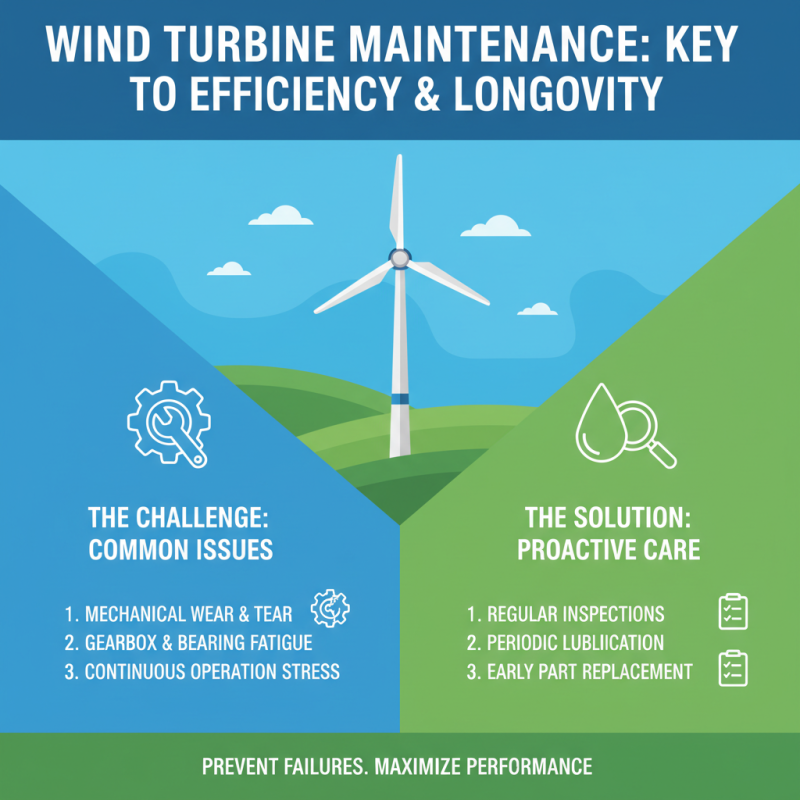

Maintaining wind turbines is crucial to ensure their efficiency and longevity, yet common issues can disrupt their performance. One prevalent problem is mechanical wear and tear, particularly in gearboxes and bearings. Over time, these components may experience fatigue due to continuous operation under varying environmental conditions. Regular inspections and periodic lubrication are essential for identifying wear early, ensuring that parts are replaced before they lead to more significant system failures.

Another common concern is electrical issues, such as faults in the control system or problems with the generator. These issues can often be traced back to environmental factors, including lightning strikes or extreme weather conditions. Implementing surge protection devices and conducting routine checks on electrical connections can help mitigate these risks. Furthermore, software updates to the turbine's control systems can enhance their operational efficiency and address potential vulnerabilities, significantly reducing downtime and maintenance costs.

Environmental factors play a crucial role in determining the efficiency and lifespan of wind turbines. Among these factors, temperature variations can significantly impact turbine components. For instance, extreme cold can lead to the freezing of lubricants, while excessive heat may accelerate wear and tear on the machinery. Regular maintenance becomes essential to address these impacts, such as ensuring that lubrication systems are optimized for varying temperatures and that heat dissipating mechanisms are functioning effectively.

Another critical environmental factor is corrosion, especially in coastal areas where turbines are exposed to salty air. This can degrade materials over time, leading to structural failures or decreased performance. Routine inspections and the application of protective coatings can mitigate these effects, prolonging the turbine's operational life and maintaining its energy output efficiency.

Additionally, factors like wind patterns and turbulence must be considered when siting turbines, as these elements influence not only the immediate energy generation but also the overall wear on turbine systems. By understanding and adapting to these environmental influences, operators can enhance the reliability of wind energy systems.