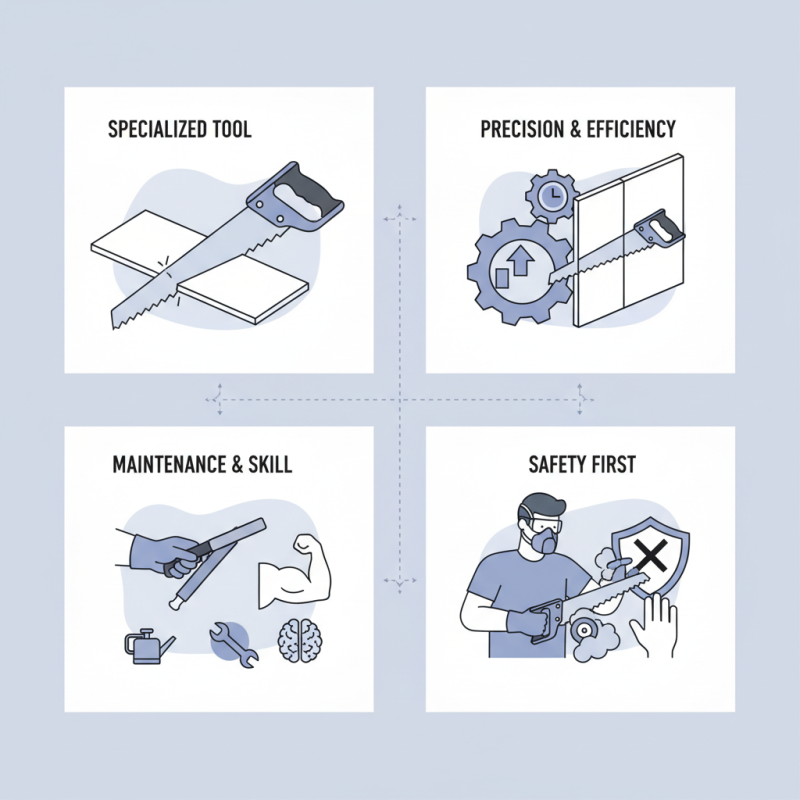

A Plaster Saw is a specialized tool designed for cutting through plaster materials. This tool is essential in various construction and renovation projects. Using a plaster saw requires skill and precision. It allows users to create clean cuts, making it ideal for fitting and adjusting plasterboard or other related materials.

Understanding how to use a plaster saw effectively can save time and reduce waste. A proper grip and controlled movements are crucial when working with this tool. Beginners might find it challenging. The teeth of the saw can become dull quickly if not cared for. Regular maintenance is key to ensuring longevity.

When using a plaster saw, safety is paramount. Dust can be a concern, so wearing protective gear is important. Many overlook this step. Remember, a simple mistake can lead to injuries or poor results. Keeping these details in mind will enhance the plaster cutting experience significantly.

A plaster saw is a specialized tool designed for cutting plaster and drywall. Its unique blade allows for precision and control while minimizing damage to surrounding materials. Most plaster saws feature a serrated edge designed to slice through the dense texture of plaster efficiently.

In construction, plaster saws are indispensable. According to industry reports, over 65% of drywall installations involve some form of plaster cutting. This tool's efficiency is crucial, especially for professionals who aim to reduce waste during projects. However, inexperienced users may struggle with the saw's technique. A miscalculated cut can lead to additional repairs or wasted materials.

Proper use of a plaster saw requires practice. The grip and angle of the saw can significantly affect the quality of the cut. Many users find it challenging to maintain a steady hand, leading to uneven edges. This can be frustrating, as it requires rework—taking precious time away from the project. Learning from mistakes is part of the process, but each error highlights the need for skill development in using such tools effectively.

A plaster saw is a specialized tool designed for cutting through plaster and drywall. Its key features include a serrated blade, a sturdy handle, and a lightweight design. The blade is typically made from high-carbon steel, which enhances durability and strength. A high-quality plaster saw allows for precise cuts and reduces the effort required during the cutting process.

The ergonomic design of the handle is crucial. It enables better grip and control, reducing the chance of strain during prolonged use. According to industry reports, improper tool design can lead to a 30% increase in user fatigue. This statistic highlights the importance of selecting the right tool for the job. Plaster saws usually range from 10 to 12 inches in length, striking a balance between maneuverability and effectiveness.

In practice, users often find that serrated blades work better on harder surfaces. However, some may struggle with deeper cuts. This can be a significant limitation when precision is needed. Research indicates that 25% of drywall installation errors relate to tool choice and technique. It’s essential for users to reflect on their methods and tools. Small adjustments can lead to better results in plastering projects.

A plaster saw is an essential tool in construction and renovation projects. It is designed for cutting through plaster materials with precision. The blade is typically fine-toothed, which helps achieve a smooth cut. Many professionals rely on this tool to create neat edges and openings when working with walls and ceilings.

Common uses of a plaster saw include cutting out sections for light fixtures or electrical wiring. It helps in making accurate cuts to ensure proper fit and finish. When repairing walls, it’s often used to remove damaged plaster before applying new material. This tool can also come in handy for creating decorative patterns or designs on plaster surfaces. However, using a plaster saw requires some practice. New users might struggle with creating straight lines initially.

Another common application is during demolition work. The saw allows for controlled cuts, helping to minimize damage to surrounding areas. Yet, caution is necessary. Overzealous cutting can lead to mistakes, requiring additional repairs. Not everyone achieves perfect results on their first try. With time and experience, users can develop better techniques and improve their skills. A plaster saw is versatile but demands respect and careful handling.

Using a plaster saw can be a practical solution for various projects. However, safety should always be a priority. Before using the tool, ensure you wear protective gear. Safety goggles will shield your eyes from dust and debris. A dust mask is also essential to avoid inhaling particles.

When handling the plaster saw, hold it firmly and keep your focus. It’s easy to get distracted, especially with the sound it makes. Make sure your workspace is clear of obstacles. Check the blade before each use. Sometimes, it may have small nicks that can affect performance. A dull blade can lead to accidents.

As you cut through plaster, apply steady pressure. Too much force can cause the tool to slip. Take your time. If you feel uncertain, practice on scrap material first. Each cut helps you understand the tool better. Remember, even experienced users can make mistakes. It’s okay to double-check your measurements before making a final cut. Focus on maintaining control for the best results.

A plaster saw is a useful tool for cutting various plaster materials. Regular maintenance ensures optimal performance. Start by keeping the blade clean. Dust and debris can build up during use. This build-up affects cutting efficiency. Wipe the blade after each use to eliminate residue.

Check the blade frequently for damage. A dull blade can lead to poor cuts. Replace it if you notice significant wear. Make adjustments to the saw settings according to the task at hand. Precision is key when working with plaster.

Store the saw in a dry place. Moisture can lead to rust, which shortens the lifespan of the blade. Consider using a protective case. Regular checks are essential. Inspect the saw for any signs of wear or malfunction. Addressing small issues promptly can prevent bigger problems down the line.