In the woodworking and construction world, the term "saw-swing" resonates deeply. Renowned expert John Peters once stated, “A perfect cut is a dance of precision, and the saw-swing is the rhythm.” This phrase captures the essence of how saw swings operate in various machines. Understanding this mechanism is vital for anyone working with saws.

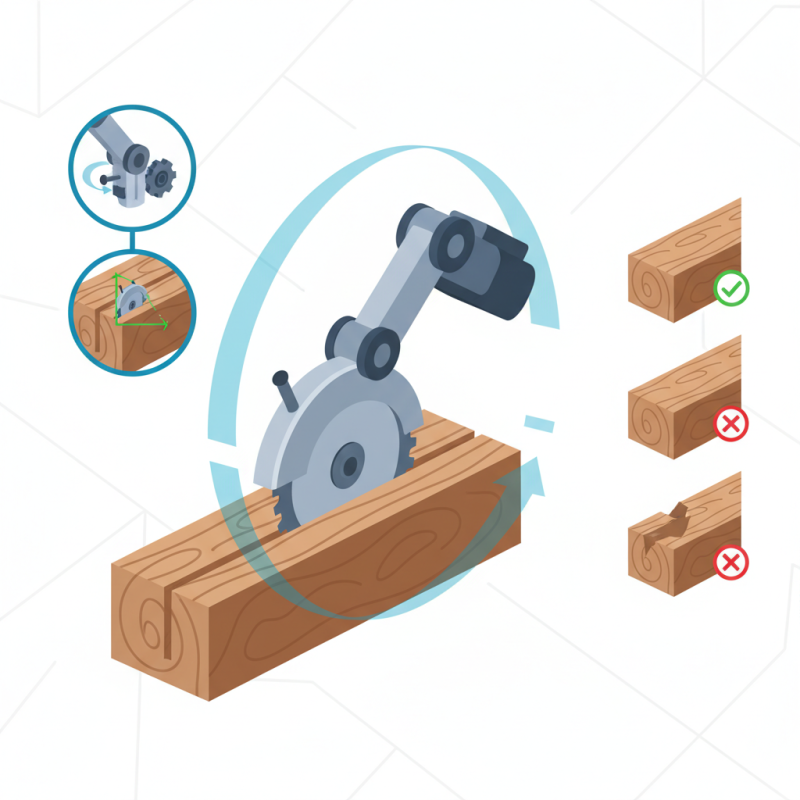

The saw swing refers to the arc through which the cutting blade travels. This motion allows for smoother cuts and enhances the tool's efficiency. It is fascinating how a simple pivot can significantly impact accuracy. However, many overlook the nuances of how saw swings affect different materials.

Mistakes can happen without proper understanding. A faulty saw swing can lead to uneven cuts and wasted materials. Learning the optimal angle and swing for each task is essential. There is always room for improvement, even for seasoned professionals. Reflecting on the mechanics involved can enhance one's craft dramatically. The saw-swing is not just a function; it embodies an art form in woodworking.

In woodworking, a saw swing is a pivotal mechanism. It describes the movement of the saw blade as it cuts through materials. This functionality is essential for precision and efficiency. The swing motion influences the type of cuts achievable, allowing for smooth or angular finishes.

According to industry reports, a saw with a larger swing can enhance productivity. A swing range of 0 to 45 degrees often provides versatility. For instance, it enables craftsmen to make compound cuts with ease. However, there's a delicate balance. A swing that's too wide may result in loss of control. Such discrepancies can lead to inaccurate cuts, impacting the final product's quality.

Understanding the saw swing also aids in safety. Properly adjusted swings minimize the risk of kickback. Reports indicate that nearly 30% of woodworking accidents stem from improper tool use. Learning to control the saw swing could reduce some of these risks. Yet, not all woodworkers prioritize this education, leading to preventable mistakes.

A saw swing is an essential mechanism in many cutting tools. It allows the blade to move back and forth efficiently. This motion is often utilized in band saws and some table saws. The saw swing aids in a smooth cutting process, providing versatility for different materials.

Key components of a saw swing include the pivot point, the motor, and the blade tensioning system. The pivot point determines the angle and range of motion. The motor drives the swing and often comes with adjustable speeds. The blade tension system ensures stability and accuracy during operation.

Tips: Always check the blade for wear and tear before starting a project. A dull blade can cause rough cuts and tear materials. Additionally, maintain a clean workspace to avoid distractions and accidents.

Improper adjustment of the swing angle may lead to uneven cuts. Testing the tool on scrap material can help you get a better feel for the swing. This practice can reveal potential issues before you start on your actual project.

The market for saw swings has evolved significantly. Different types suit various needs, from carpentry to metalworking. A comparative analysis reveals diverse features and functionalities among popular models. For instance, a recent industry report indicated that nearly 45% of users prioritize precision over speed when selecting a saw swing.

One common type includes manual saw swings, which offer finer control. These are ideal for delicate tasks but require more physical effort. Electric saw swings, on the other hand, provide efficiency and consistency. Data shows that electric versions improve productivity by over 30%. However, they can be heavier and more complex for beginners. It's interesting to see how user experience varies greatly.

Safety is another critical area of concern. About 25% of users report minor injuries due to improper handling of saw swings. This statistic highlights the need for comprehensive training and awareness. Many models come with safety features, yet some users overlook them. This points to a crucial gap in effective usage and education in the market. Engaging with these tools demands both respect and knowledge.

As the market grows, so must the understanding of these tools. Choosing the right saw swing involves weighing functionality against potential risks. Balancing effectiveness and safety will become essential for users.

When using a saw swing, safety must be a priority. The device operates through a swinging motion, allowing for precise cuts. Proper handling is essential to prevent accidents. Always wear safety goggles. They protect your eyes from debris. Hearing protection is also important. The noise can be loud.

Tips for safe operation include maintaining a firm grip on the handles. This ensures better control. Position yourself correctly to avoid swinging into your body. Check the tension of the swing before each use. A loose swing can lead to mistakes.

Always be aware of your surroundings. Keep the area clear of obstacles and bystanders. Avoid distractions while cutting. If you feel fatigued, take a break. Rushing can lead to errors. Reflect on your technique regularly. Continuous improvement is key to safe usage.

Saw swings are fascinating tools that provide both efficiency and precision in various cutting applications. Their design allows for a smooth swinging motion, enabling users to make clean cuts effortlessly. This precision is critical in industries where accuracy matters, such as woodworking or metal fabrication. A well-executed cut not only enhances the quality of the work but also saves time, reducing material waste.

When assessing performance metrics, several factors come into play. The speed of the swing, the angle, and the blade type can significantly influence the outcome. Efficiency is often measured by how quickly a task is completed without sacrificing the integrity of the cut. However, achieving the perfect balance can be challenging. Users may find themselves struggling to maintain speed while ensuring accuracy, leading to potential errors.

Moreover, improper technique can result in inconsistent cuts. Over time, one may reflect on their methods and notice patterns of inefficiency. Adjusting the swing's angle or grip can improve results, but it requires practice. Realizing the areas that need improvement is essential for anyone looking to master saw swings in their projects.