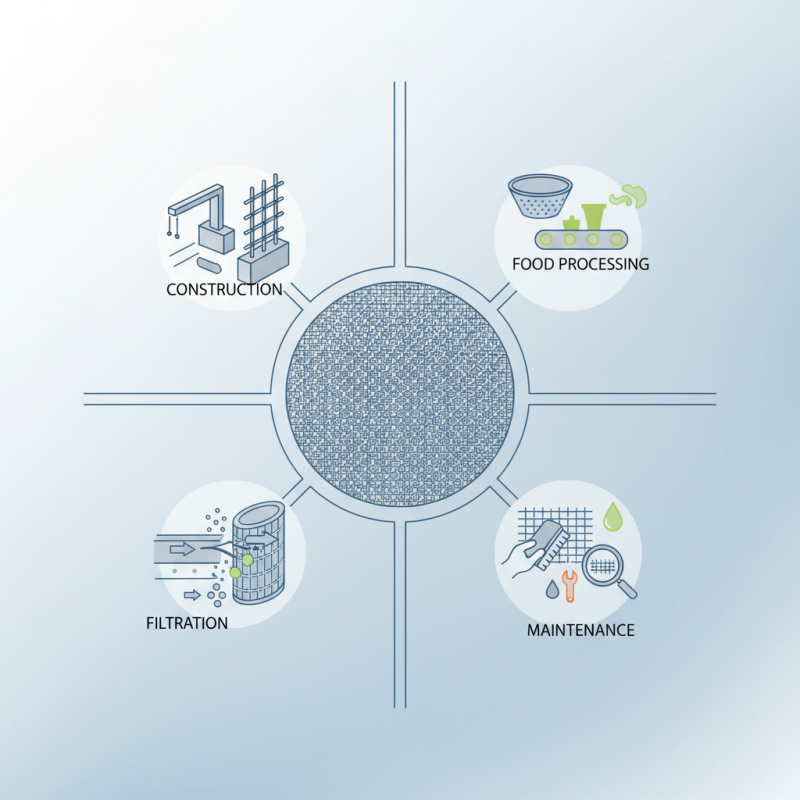

stainless steel wire mesh is an essential material in various industries. Its durability and corrosion resistance make it a favorite among manufacturers. According to a 2021 report by Market Research Future, the global stainless steel wire mesh market is expected to reach $9 billion by 2025. This growth highlights its importance in sectors such as construction, food processing, and filtration.

In construction, stainless steel wire mesh provides strength and stability. It is used in concrete reinforcement and safety barriers. In the food processing industry, it plays a crucial role in ensuring hygiene and safety. The mesh allows air circulation while preventing contaminants. However, over-reliance on a single material can lead to challenges. Understanding the limits of stainless steel wire mesh is crucial.

Additionally, in filtration applications, stainless steel wire mesh is invaluable. It offers precise filtration for liquids and gases. Yet, some users overlook the maintenance needed for optimal performance. Regular cleaning and inspection can prevent issues that may arise from neglect. Balancing efficiency and care is vital in all its applications.

Stainless steel wire mesh is a versatile material widely used in various industries. It is made from stainless steel, known for its corrosion resistance and durability. The composition typically includes iron, chromium, and nickel. This combination gives the mesh its strength and longevity. The manufacturing process involves weaving thin wires of stainless steel into a grid-like pattern, resulting in a product that can withstand different environmental conditions.

The applications of stainless steel wire mesh are numerous. It is often used in filtration systems due to its ability to trap fine particles. In construction, it serves as reinforcement for concrete structures. Additionally, its aesthetic appeal makes it popular in decorative applications.

However, while stainless steel is durable, it can be susceptible to certain environmental factors, such as extreme saline exposure. This aspect sometimes requires careful consideration in specific projects to ensure longevity. Overall, understanding the composition of stainless steel wire mesh is crucial to leveraging its benefits effectively.

Stainless steel wire mesh comes in various types, each suited for specific applications. Woven wire mesh is the most common type. It has a simple design and provides excellent strength. Typically, it is used in filtration and protection. It can filter out small particles while allowing liquids or gases to pass through.

Another variety is welded wire mesh. This type offers more strength due to its welded intersections. It is often used in construction, reinforcing concrete. The mesh can also serve as a barrier. It’s durable but may require less flexibility. This can be a disadvantage in some projects.

There are also specialized meshes like hexagonal wire mesh. It is often used in poultry farming. This mesh type helps keep animals in while securing against larger predators. Each type has its unique properties, making them suitable for different environments. Understanding these differences is crucial. Choosing the right type of mesh can sometimes be challenging and may require careful consideration of factors like cost and necessity.

Stainless steel wire mesh is widely used across various industries. Its durability and corrosion resistance make it ideal in construction, food processing, and filtration applications. According to a recent industry report, the global stainless steel wire mesh market is expected to reach USD 1.2 billion by 2026, growing at a CAGR of 4.5%. This indicates a rising demand driven by its versatile uses.

In construction, stainless steel wire mesh supports reinforced concrete and safety barriers. It enhances structural integrity while withstanding harsh weather conditions. In food processing, it is utilized for sieving and filtering, ensuring product safety. A study revealed that nearly 70% of food manufacturers prefer stainless steel mesh for its hygienic properties. However, some manufacturers face challenges in sourcing quality mesh that meets industry standards.

In the automotive sector, stainless steel wire mesh plays a crucial role in exhaust systems, providing durability and noise reduction. The aerospace industry also uses this material for its lightweight and strong attributes. While the applications are vast, some industries struggle with high costs and limited suppliers. Many companies need to reflect on their supply chain strategies to ensure consistency and quality in their products. Investing in better sourcing could mitigate these issues.

Stainless steel wire mesh offers several advantages that make it a preferred choice in various industries. One major benefit is its resistance to corrosion. According to a 2021 industry report, stainless steel can withstand harsh environments better than other materials. This quality significantly extends the lifespan of products and reduces maintenance costs.

Another advantage of stainless steel wire mesh is its high tensile strength. In construction and manufacturing, projects often require materials that can bear heavy loads. Stainless steel wire mesh is known for its durability in these applications. Data shows that it can endure weights up to twice as much as wires made from other metals.

Stainless steel is also non-toxic and safe for food contact, making it ideal for the food processing industry. However, using stainless steel presents challenges. It can be more expensive upfront compared to alternatives like plastic or aluminum. Additionally, not every stainless steel type is suitable for all environments. Choosing the right grade is essential for optimal performance.

| Dimension | Stainless Steel Wire Mesh | Other Materials |

|---|---|---|

| Corrosion Resistance | Excellent | Variable |

| Durability | High | Moderate to Low |

| Temperature Resistance | High | Low |

| Maintenance | Low | High |

| Weight | Light | Heavy |

| Applications | Food industry, construction, filtration | Limited applications, less effective |

Stainless steel wire mesh is durable and versatile. However, it requires proper care to ensure longevity. Regular maintenance is crucial for its performance. Here are some tips for keeping your stainless steel wire mesh products in top shape.

Regular cleaning is essential. Use mild detergent and warm water. This helps remove dirt and debris without scratching the surface. Avoid harsh chemicals, as they can cause damage. For stubborn stains, a soft brush can be helpful. Remember, cleanliness affects both appearance and functionality.

Inspect your wire mesh often. Look for signs of wear or rust. Even small areas of corrosion can lead to bigger problems. If you notice issues, address them immediately. Sometimes, a simple touch-up can extend the life of your mesh. Taking these steps might seem tedious, but it's worth the effort. Proper care can save you from costly replacements later on.